OEM/ODM Factory Aluminum Metal Panels - Perforated aluminum veneer – Jixiang Detail:

Product overview:

Perforated aluminum veneer is a refined product of aluminum veneer. The automatic numerical control punching machine imported from Germany can easily realize the processing of various complex hole shapes of punching aluminum veneer, meet the customer’s requirements for various hole shapes, irregular hole diameters and gradual change holes of punching aluminum veneer, at the same time, ensure the accuracy of punching processing, meet the high standards of architectural design to the greatest extent, and fully express the innovative ideas of architectural design.

Punching aluminum veneer mainly uses aluminum alloy plate with high strength as the base material. The thickness is between 2 mm and 4 mm. The size and specification of punching aluminum veneer are elastic, and there are many types to choose from. The high-quality punching aluminum veneer will be added with reinforcing rib at the back when processing, so that the punching aluminum veneer can fix the surrounding stress when bearing the load of vertical layout, strengthen the bearing capacity and stability of the aluminum veneer, and strengthen the strength and thickness of the aluminum veneer. This provides a good material choice for designers in the application of aluminum veneer materials.

Product features:

1. It can be customized on demand to meet the personalized needs of customers. The maximum standard size is 1500mm * 4000mm

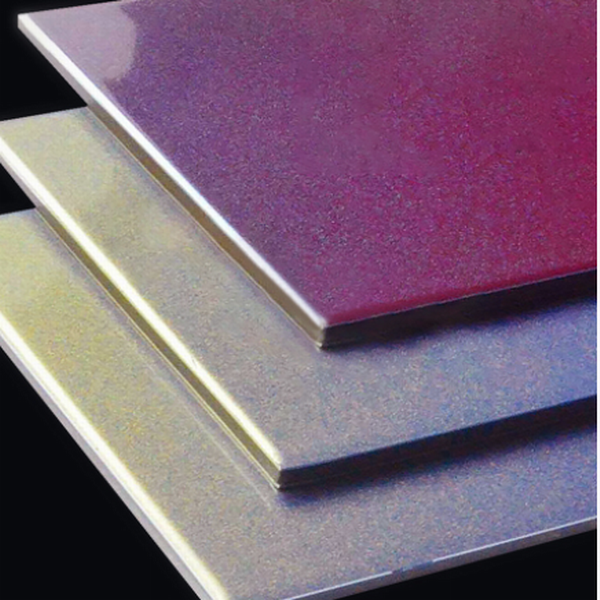

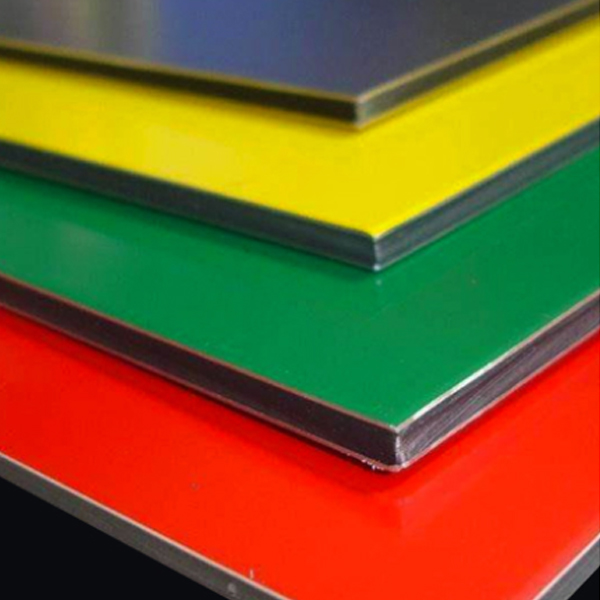

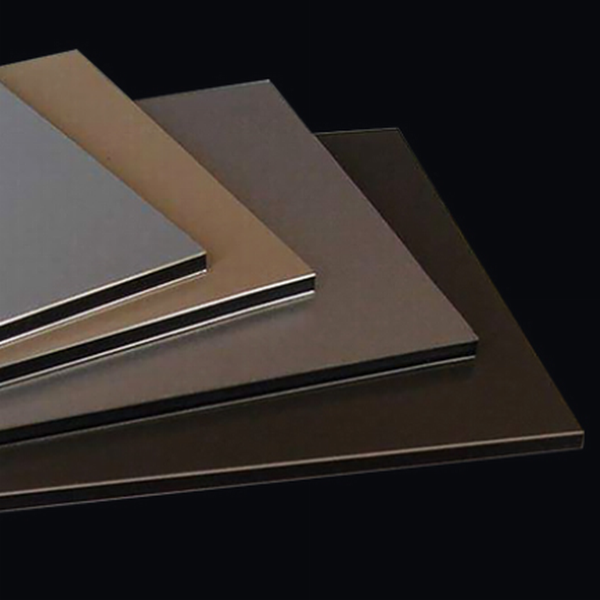

2. Variety: Design of color, pass, punching rate, etc.

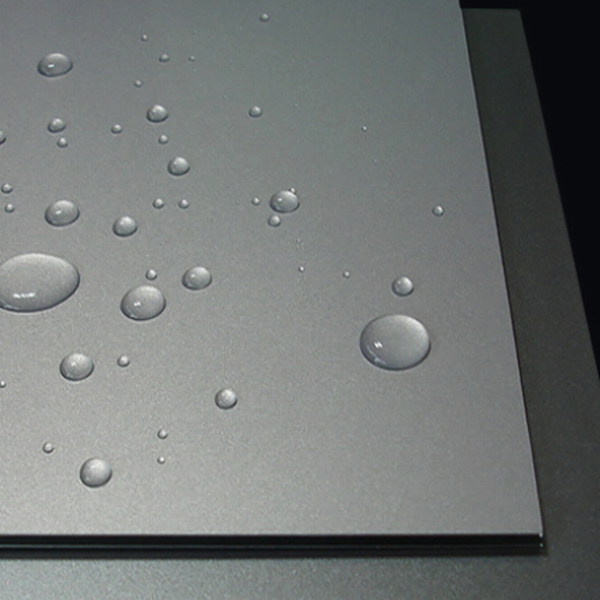

3. Fluorocarbon paint is corrosion-resistant, UV resistant and colorfast.

5. Convenient installation and construction, reduce installation and maintenance costs.

6. Aluminum alloy material can be completely recycled and reused, which is green and environmental protection.

7. Quality assurance, durable.

Applications:

The perforated aluminum veneer can meet the needs of various functions, and is widely used in the exterior wall, ceiling, interior wall and so on.

Product detail pictures:

Related Product Guide:

We attempt for excellence, company the customers", hopes to be the top cooperation team and dominator company for personnel, suppliers and customers, realizes price share and continual marketing for OEM/ODM Factory Aluminum Metal Panels - Perforated aluminum veneer – Jixiang, The product will supply to all over the world, such as: Buenos Aires, Riyadh, Borussia Dortmund, Now, we are trying to enter new markets where we do not have a presence and developing the markets we have now the already penetrated. On account of superior quality and competitive price , we'll be the market leader, be sure to don??¥t hesitate to contact us by phone or email, if you are interested in any of our solutions.

The factory workers have a good team spirit, so we received high quality products fast, in addition, the price is also appropriate, this is a very good and reliable Chinese manufacturers.

-

Lowest Price for Aluminum Sheet Metal - Hyperb...

-

Wholesale Discount 36 X 36 Aluminum Sheet - Hy...

-

Special Price for Aluminum Composite Metal - N...

-

Factory wholesale Perforated Aluminum Composite...

-

2020 Good Quality Pe Coating Aluminum Composite...

-

Big discounting Anexa Aluminium Composite Panel...