Manufacturer of Aluminum Extrusion Panels - Perforated aluminum veneer – Jixiang Detail:

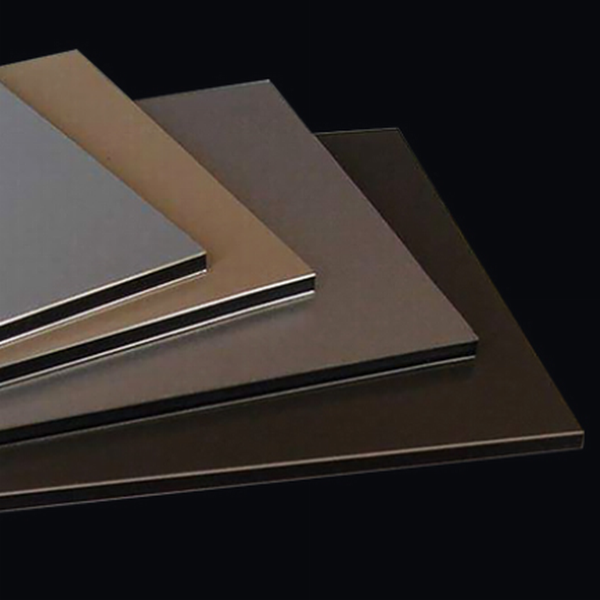

Product overview:

Perforated aluminum veneer is a refined product of aluminum veneer. The automatic numerical control punching machine imported from Germany can easily realize the processing of various complex hole shapes of punching aluminum veneer, meet the customer’s requirements for various hole shapes, irregular hole diameters and gradual change holes of punching aluminum veneer, at the same time, ensure the accuracy of punching processing, meet the high standards of architectural design to the greatest extent, and fully express the innovative ideas of architectural design.

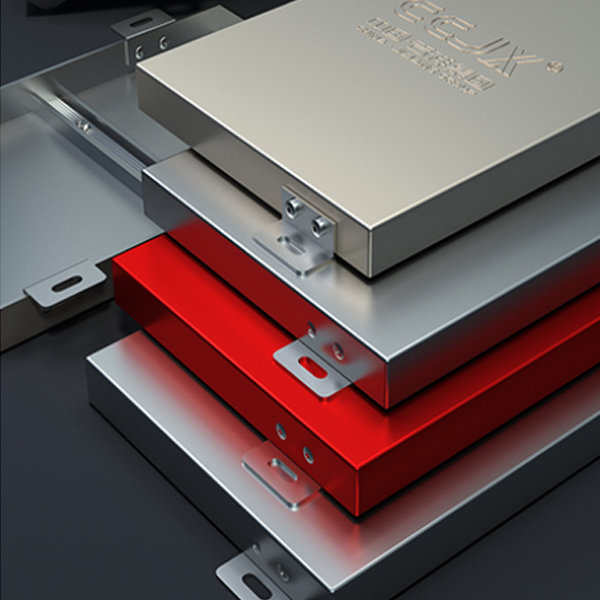

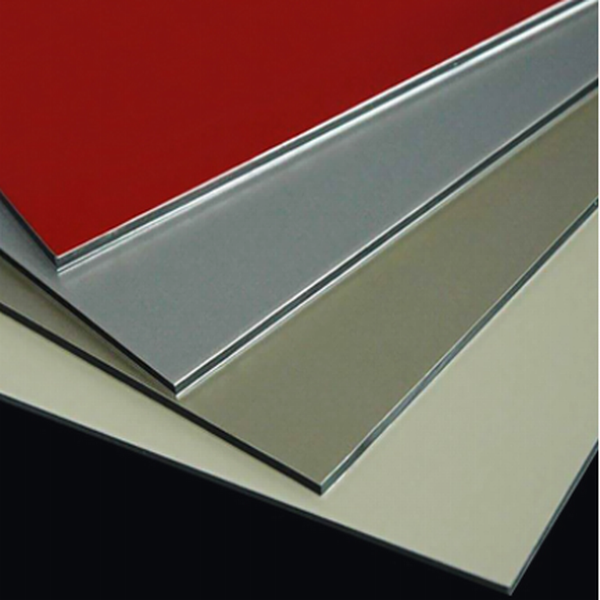

Punching aluminum veneer mainly uses aluminum alloy plate with high strength as the base material. The thickness is between 2 mm and 4 mm. The size and specification of punching aluminum veneer are elastic, and there are many types to choose from. The high-quality punching aluminum veneer will be added with reinforcing rib at the back when processing, so that the punching aluminum veneer can fix the surrounding stress when bearing the load of vertical layout, strengthen the bearing capacity and stability of the aluminum veneer, and strengthen the strength and thickness of the aluminum veneer. This provides a good material choice for designers in the application of aluminum veneer materials.

Product features:

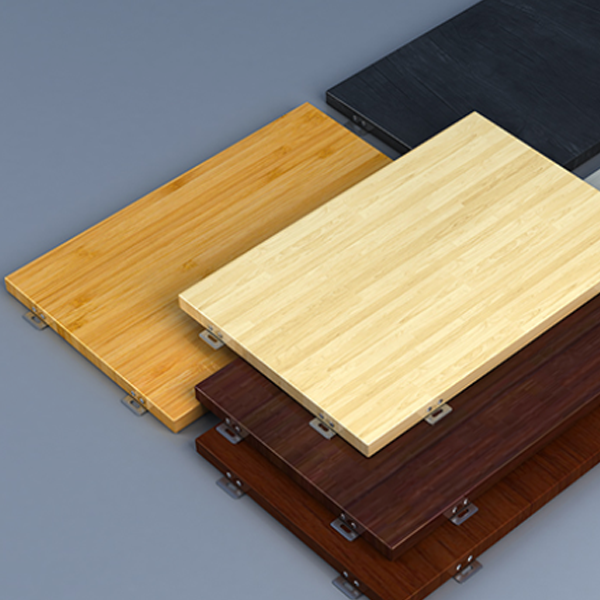

1. It can be customized on demand to meet the personalized needs of customers. The maximum standard size is 1500mm * 4000mm

2. Variety: Design of color, pass, punching rate, etc.

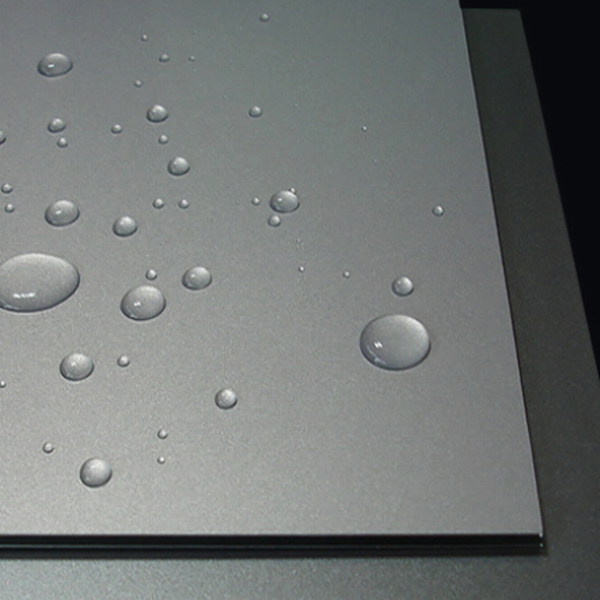

3. Fluorocarbon paint is corrosion-resistant, UV resistant and colorfast.

5. Convenient installation and construction, reduce installation and maintenance costs.

6. Aluminum alloy material can be completely recycled and reused, which is green and environmental protection.

7. Quality assurance, durable.

Applications:

The perforated aluminum veneer can meet the needs of various functions, and is widely used in the exterior wall, ceiling, interior wall and so on.

Product detail pictures:

Related Product Guide:

We always get the job done being a tangible workforce making sure that we can easily give you the very best quality as well as finest selling price for Manufacturer of Aluminum Extrusion Panels - Perforated aluminum veneer – Jixiang, The product will supply to all over the world, such as: Buenos Aires, Southampton, Cairo, We have been perfectly devoted to the design, R&D, manufacture, sale and service of hair products during 10 years of development. We have introduced and are making full use of internationally advanced technology and equipment, with advantages of skilled workers. "Dedicated to providing reliable customer service" is our aim. We are sincerely looking forward to establishing business relationships with friends from at home and abroad.

Good quality, reasonable prices, rich variety and perfect after-sales service, it's nice!

-

PriceList for Compbond Aluminum Composite Panel...

-

Manufacturer of 24 Ft Aluminum Walk Board - Fi...

-

Factory Cheap Hot 24 X 36 Aluminum Sheet - 4D ...

-

Popular Design for Composite Panel Aluminium -...

-

Low MOQ for Fire Retardant Aluminium Composite ...

-

Super Lowest Price Expandable Aluminum Sheet -...