The Future of Workspace

Breaking the Traditional Definition

Reimagining the Spatial Narrative

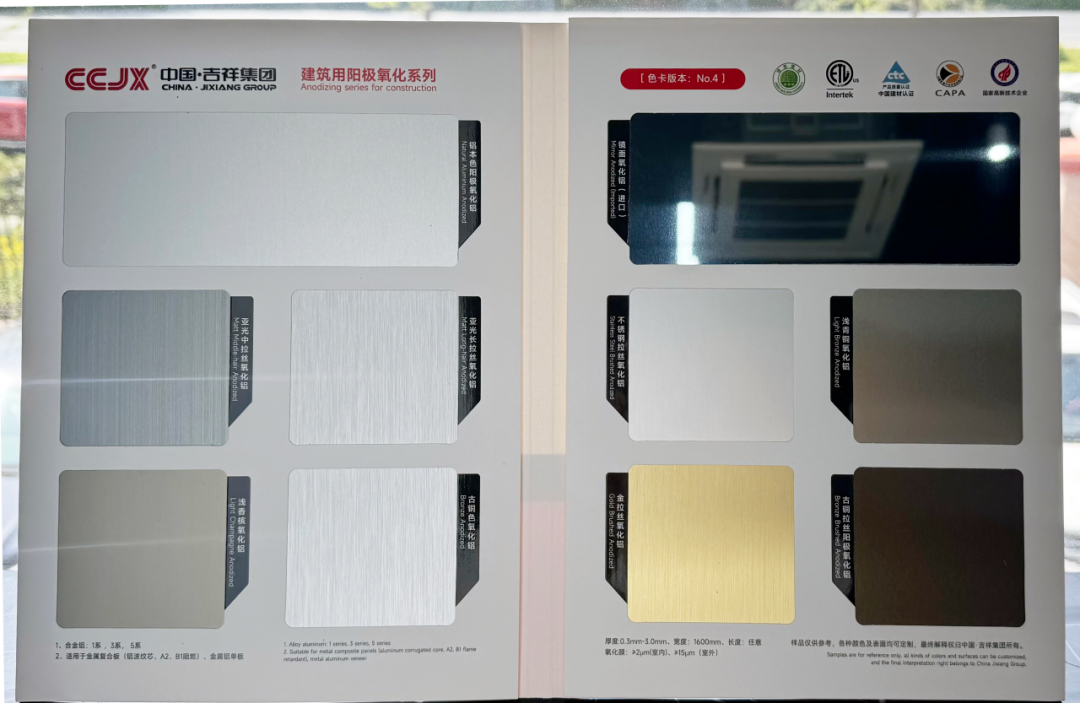

Anodized Aluminum Composite Panels (Grade A2) are a new building material made from a high-strength aluminum alloy substrate, surface-treated through an anodizing process, and then composited with polymer materials or metals. They not only retain the lightweight properties of aluminum but also offer exceptional weather resistance, rich colors, and a premium texture. They are ideal for architectural curtain walls, interior decoration, and high-end equipment.

In space design, anodized aluminum metal composite panels can be used as the preferred material for interior wall decoration. The ceiling cleverly uses anodized aluminum mirror composite, making the overall space visually full of futuristic technology.

The anodized aluminum composite panels form a dense oxide film on their surface, imparting a cool, deep space gray metallic luster. Their nano-scale texture creates a fluid, technological aura under natural light. As a Class A fireproof material, their core layer utilizes a nano-silicate core material, creating a thermal barrier in the event of fire. With a fire resistance limit exceeding two hours, they provide a safe barrier for modern office environments.

In terms of performance, the panels feature an anti-fingerprint coating and a scratch-resistant surface treatment, ensuring they retain their mirror-like finish even after long-term use. Precision prefabrication and installation shorten construction time by 40%. "Recyclable and compliant with green building standards," they offer innovative solutions for sustainable office work.

Anodized Aluminum Grade A2 Metal Composite Panels:

A perfect combination of durability and aesthetics

1. Highly Appearing: The anodizing process imparts a delicate luster and rich colors (such as champagne gold, titanium silver, and space gray), elevating the building's class.

2. Ultra-Weatherproof: The dense oxide layer resists UV rays and corrosion, remaining colorfast and non-fading for 20 years, making it suitable for extreme climates.

3. Lightweight: Weighing only one-third of stainless steel, it reduces building loads and facilitates construction.

4. High Strength: The composite structure enhances impact resistance, providing superior wind pressure and earthquake resistance.

5. Easy Maintenance: The smooth surface resists dust and self-cleans with rainwater, eliminating the need for frequent cleaning.

6. Environmentally Friendly and Energy-Saving: 100% recyclable, it reflects sunlight, reducing building energy consumption.

Post time: Aug-21-2025